Bridge Bearing

Bridge bearing is a device installed in between upper plate and bridge peer to support upper plate, reduce shock on the superstructure and deliver force to substructure safely.

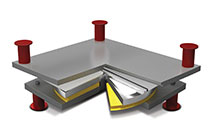

Rubber Bearing

- Vertical Capacity : MAX Loading Condition 30,000kN

- Design Capacity : Less than 70% rubber height (Normal Condition), Less than 150% rubber height (Under Earthquake)

- Type : Fixed, One direction, Omni-direction

- Horizontal Displacement : shear deformation of elastic body

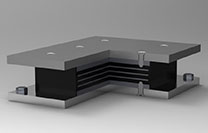

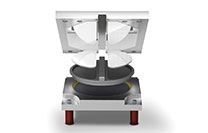

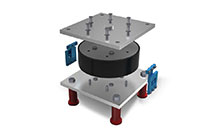

Pot Bearing

One direction

Fixed

Omni-direction

A Cross View

- Vertical Capacity : MAX Loading Condition 60,000kN

- Type : Fixed, One direction, Omni-direction

- Sliding function : PTFE + STAINLESSSTEEL PLAT

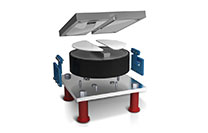

Friction Pot Bearing

One direction

Omni-direction

- Vertical Capacity : MAX Loading Condition 60,000kN

- Type : One Direction, Bi-direction

- Sliding function : Filled PTFE + POT

- Maintenance : Excellent friction rate and simple maintenance as it connects upper and bottom part using bolting and socket in replacing the main body

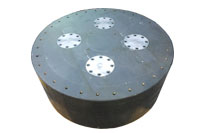

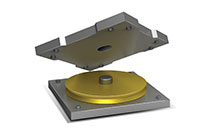

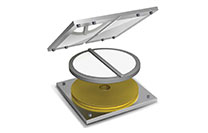

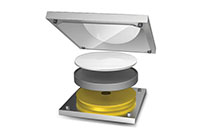

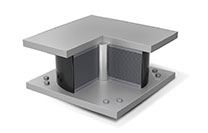

Disc Bearing

Fixed

One direction

Omni-direction

A Cross View

- Vertical Capacity : MAX Loading Condition60,000kN

- Design Surface Pressure : 35MPa

- Type : Fixed, One direction, Omni-direction

- Sliding function : PTFE+SLIDE PLATE

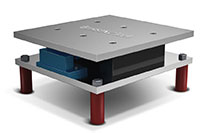

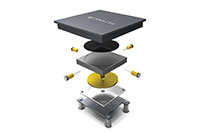

VRSB / Vibration Reduction Spherical Bearing

Fixed

One direction

Omni-direction

A Cross View

- Vertical Capacity : MAX Loading Condition 20,000kN

- Structure : Spherical Bearing + Elastomeric Bearing

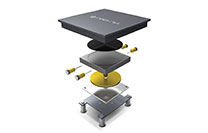

Lead Rubber Bearing (LRB)

Quadrangle LRB

Round LRB

- Vertical Capacity : MAX Loading Condition 20,000kN

- Design Surface Pressure : 12~15MPa

- Design Capacity : Less than 70% rubber height (Normal Condition), Less than 200% rubber height ( Under Earthquake)

- Type : Round or Quadrangle (Arbitrary form can be manufactured)

- Height of Bearing : Determined by the construction volume of upper plate and unique cycle of structure Complements the defect of enlarging bearing height by developing SLIDING LRB

Multi-Lead Core Rubber Bearing (MLRB)

- Vertical Load : Maximum load capacity is 20,000 kN

- Design Axial Stress : 12~15MPa (for Bridge)

- Design Lateral displacement : Less than 70% of total rubber height (at normal times), Less than 200% of total rubber height (at Earthquake)

- Lead core : 4-axis (Rectangular & Circular type)

- Height of Bearing : Equal to single lead core

Energy Dissipation Bearing

EDS(Omnidirectional)

OMEDS(One Direction)

EDS PLUS

- Composition : Disc bearing, MER spring (polyurethane)

- Vertical Capacity : MAX Loading Condition 60,000kN

- Design Capacity : Movement by horizontal sliding of PTFE, and pressure and tensile force of spring(same with pot bearing)

- Type : Quadrangle

- Design Surface Pressure : 35MPa

High Damper Rubber Bearing

HDRB

A Cross View

- Vertical Capacity : MAX Loading Condition 20,000kN

- Design Capacity : Less than 70% of rubber height (Normal Condition), Less than 200% of rubber height ( Under Earthquake)

- Type : Round or Quadrangle (Arbitrary form can be manufactured)

- Height of Bearing : Determined by the construction volume of upper plate and unique cycle of structure

Expansion Joint

Expansion Joint is a device installed to absorb the movement gap between superstructure and substructure caused by movement and circulation of superstructure by elasticity of temperature change, dry contraction of concrete, cliff and live load and to minimize shock when vehicles pass.

Omni Directional Expansion Joint (U.O.J)

- Product : Omni Directional Expansion Joint

- Scope of Elasticity : 50~700mm

- Composition : Finger Plate+Base Plate+Anchor Bolt+Rubber Sheet+Gap control rubber

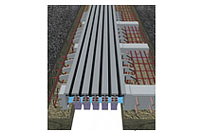

Finger Type Expansion Joint

- Product : Finger Type Expansion Joint (UCF-S)

- Scope of Elasticity : 50~700mm

- Composition : Finger Plate+Base Plate+AnchorBolt + Rubber Sheet

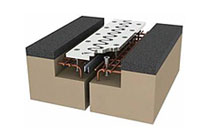

Rail Type Expansion Joint

- Product : Rail Type (URJ)

- Scope of Elasticity : 80~1280mm

- Composition : Steel Rail + Support Beam + Rubber Sheet

Soundproof Wall

It has been widely used thanks to an increase of eco-friendly and landscape focused design. UNISION eTECH produces color soundproof plate(absorption/reflection), transparent soundproof plate, light soundproof plate, high reduction soundproof plate, fireproof soundproof plate, noise interference device and soundproof tunnel.

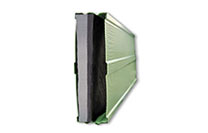

High Sound Absorption Type

It minimizes internal structure change or thick increase to have high Sound Absorption of over 85% NRC in KS (KSF 4770), and is to have grade 1 performance of NRC

- Size : Length VARmm, Width 400mm, 500mm,Thickness 100mm

- Front Plate : Zinc steel plate t=0.6~0.8mm

- Back Plate : Zinc steel plate t=1.6mm

- Sound Absorbing Material : Polyester(32-60K) t=40~66mm (Water Repellency treated), Polyester(Over 100K) t=10~30mm (Water Repellency treated)

Fireproof Type

Ceramic Fiber

High Absorbing Color Soundproof Plate

- Size : Length VARmm, Width 400mm, 500mm,Thickness 100mm

- Front Plate : Zinc steel plate t=0.6~0.8mm

- Back Plate : Zinc steel plate t=1.6mm

- Sound Absorbing Material : Polyester(32-60K) t=40~66mm(Water Repellency treated) Polyester(100K이상) t=10~30mm(Water Repellency treated) Cerak Wool 1300 Blanket (Over 100k )

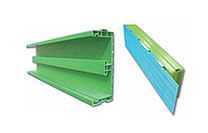

Light Weight Type

It is the lightest product in Korea with 15kg/m2 developed for bridge, existing structure and soundproof tunnel.

- Size : Length 1960mm, Width 250mm, Thickness 114.5mm

- Front Plate : PC-ASA resin t=3mm

- Back Plate : 강화 PVC 계열 t=1.6mm (multilayered structure)

- Sound Absorbing Material : Polyester t=50mm (Water Repellency treated)

Wooden & Transparent Type

Wooden and transparent types are becoming used widely according to eco-friendly soundproof wall installation for lighting and visibility.

- Size : Length 1960mm, Width 250mm, Thickness 114.5mm

- Front Plate : PC-ASA Resin t=3mm

- Back Plate : Harden PVC t=1.6mm (Multilayer)

- Sound Absorbing Material : Polyester t=50mm (Water Repellency Treated)

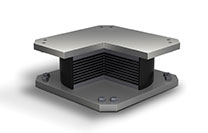

Noise Interference Device

Noise interference device is installed on top of soundproof wall to reduce noise using interference and diffraction principles of sound.

- Noise control principle of interference device

It is a sound reduction technology using the difference of diffraction. When sound penetrates an interference device, its sound directly enter on top of soundproof wall.

Sound Proof Tunnel

Soundproof tunnels are considered a representative way to perfectly prevent noise by minimizing the effect of diffracted sound taking place in the general areas of upper and lower parts in existing vertical soundproof walls.

Mold Production

Mold is a frame to produce segment and PC products (file, pole, culvert and block). We carry out design, manufacture and delivery according to segment and P.C. product shape.

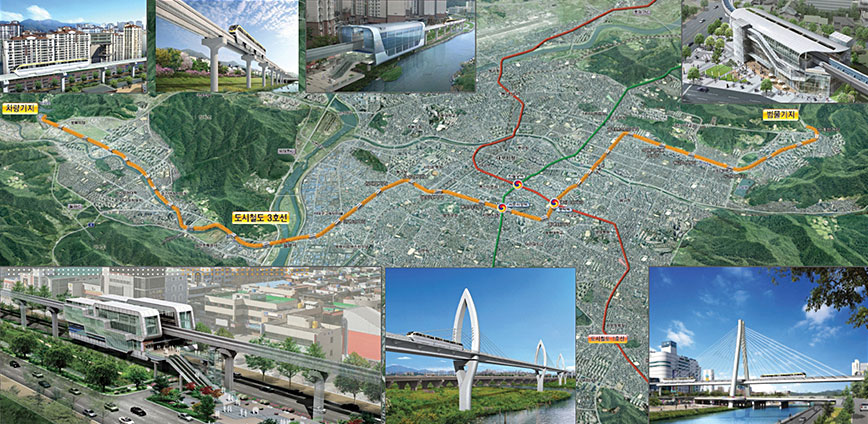

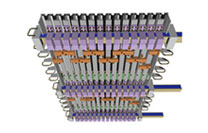

Monorail

A monorail is a railway in which the track consists of a single rail. The term is also used to describe the beam of the system, or the vehicles traveling on such a beam or track.